As part of its growth strategy, Stolz-Miras left its historical workshop in 2019 and moved to its new production facility in the Amata industrial zone (Bien Hoa City) 25km North-East from Ho Chi Minh City, designed to achive its ever increasing requirements:

- Total area: 15,700 m2,

- Workshop area: 8,000 m2 including 6,000 m2 covered,

- Office and common areas surface: 1,280 m2,

- 160 Skilled workers,

- Support and engineering teams: 40 people,

- Separated carbon steel and stainless steel work areas,

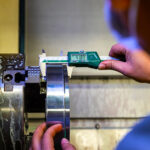

- Production departments involved in each project: warehouse, cutting, machining, manufacturing – welding – assembly, coating (painting, polishing, stripping – passivation), shipping.

Our activities, manufacturing processes and capacities are detailed here